Tumbling Machine Operator

Tumbling Machine Operator

- Job popularity

Job Description

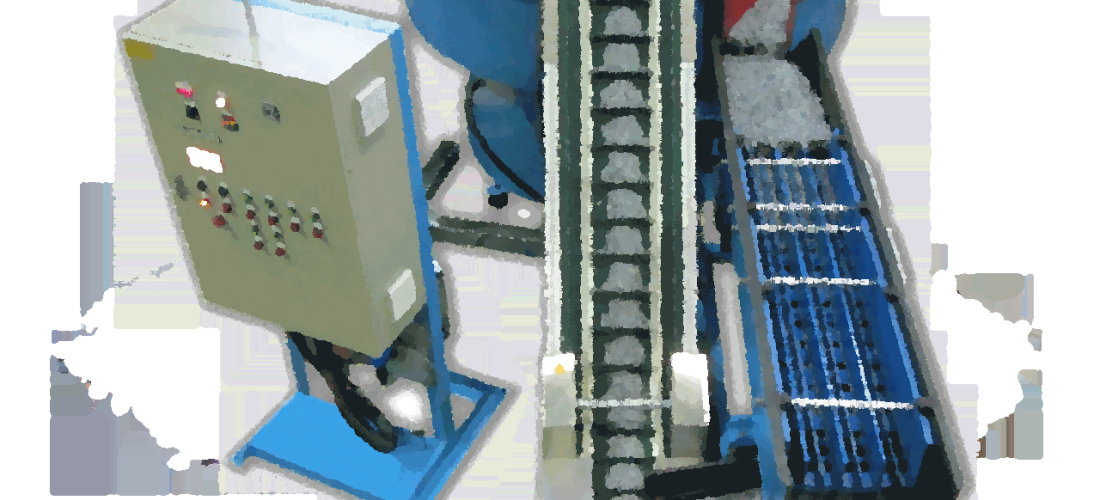

Tumbling machine operators set up and operate tumbling machines, often wet or drie tumbling barrels, designed to remove excess material and burrs of heavy metal workpieces and precious metals and to improve surface appearance, by rotating the metal pieces in a barrel together with grit and potentially water, allowing for the friction between the pieces mutually and with the grit to cause a rounding, smooth effect..

Top 2 specific things you need to know

As a Tumbling Machine Operator, you will need to master following:

Top 14 general things you need to know

More generally, a tumbling machine operator is also versed in:

- ensure equipment availability

- monitor automated machines

- monitor moving workpiece in a machine

- perform test run

- quality and cycle time optimisation

- quality standards

- remove inadequate workpieces

- remove processed workpiece

- spot metal imperfections

- supply machine

- tend tumbling machine

- troubleshoot

- types of metal

- wear appropriate protective gear

Other things it helps to know to be an excellent tumbling machine operator

It also helps to know the following:

- dry tumbling

- ferrous metal processing

- manufacturing of cutlery

- manufacturing of metal assembly products

- precious metal processing

- processes performed by tumbling

- types of metal manufacturing processes

- advise on machinery malfunctions

- characteristics of precious metals

- inspect quality of products

- keep records of work progress

- measure flatness of a surface

- metal smoothing technologies

- perform machine maintenance

- record production data for quality control

- wet tumbling

Top employers for this job

Tumbling Machine Operator (0-2 Yrs Exp.)

-

Prereqs Technology Pvt.Ltd

-

California

-

$250 - $800 / month

- Keywords :

- Ui designer,

- developer