Abrasive Blasting Operator

Abrasive Blasting Operator

- Job popularity

Job Description

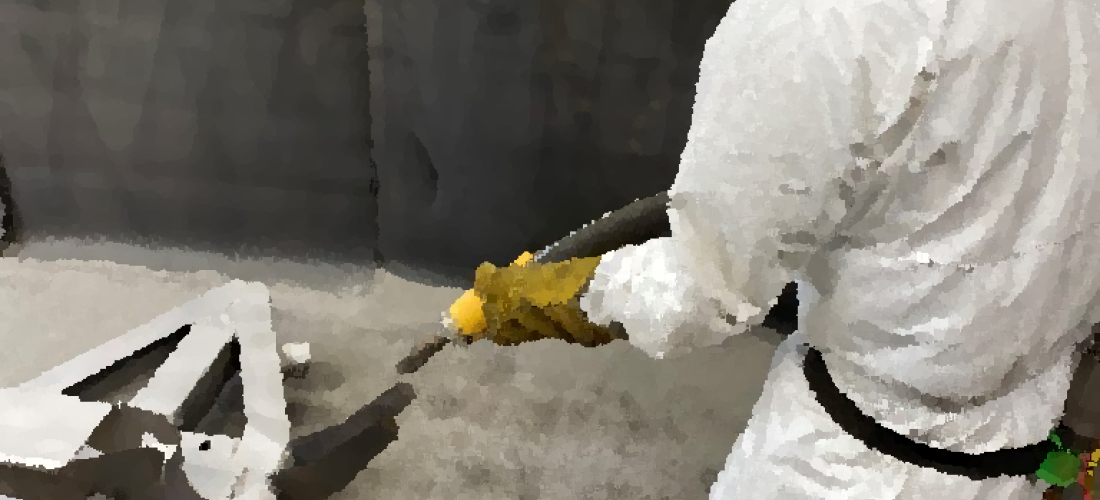

Abrasive blasting operators use the proper equipment and machinery to smoothen rough surfaces by abrasive blasting. Abrasive blasting is commonly used in the finishing process of metal workpieces and for blasting building materials used in masonry such as bricks, stones and concrete. They operate blasters or sand cabinets which forcibly thrust a stream of abrasive material such sand, soda or water, under high pressure, propelled by a centrifigal wheel, in order to shape and smoothen surfaces..

Top 3 specific things you need to know

As an Abrasive Blasting Operator, you will need to master following:

Top 6 general things you need to know

More generally, an abrasive blasting operator is also versed in:

Other things it helps to know to be an excellent abrasive blasting operator

It also helps to know the following:

- blast masonry

- ferrous metal processing

- maintain mechatronic equipment

- maintain robotic equipment

- prepare floor for terrazzo

- prepare floor for underlayment

- work in a construction team

- abrasive blasting processes

- abrasive machining processes

- advise on machinery malfunctions

- automation technology

- consult technical resources

- follow health and safety procedures in construction

- follow safety procedures when working at heights

- keep records of work progress

- mechatronics

- metal smoothing technologies

- monitor gauge

- operate automated process control

- operate sand blasting cabinet

- operate sandblaster

- prepare surface for painting

- prepare surface for plastering

- quality and cycle time optimisation

- remove processed workpiece

- robotics

- set up the controller of a machine

- spot metal imperfections

- supply machine

- troubleshoot

- use safety equipment in construction

Top employers for this job

Abrasive Blasting Operator (0-2 Yrs Exp.)

-

Prereqs Technology Pvt.Ltd

-

California

-

$250 - $800 / month

- Keywords :

- Ui designer,

- developer